THE TROJAN RANGE

The Trojan kilns are purpose built, medium to large scale kilns designed with just one thing in mind, perfect results. Everything about the Trojan is designed for purely casting results

Heat is provided from all 4 sides, the floor from under heavy duty tiles and from tubed elements in the roof.

The heat from the elements is multi-zone controlled to ensure temperature uniformity across the entire volume.

Increased size ventilation ports in the roof are motorised and programmable to open and close at any point during the cycle via the temperature controller.

The kiln has extra insulation which follows the design principle that this kiln is designed to be asked to do cycles of many weeks at a time. The additional insulation serves two purposes, to assist in retaining heat during the long annealing periods and also to ensure that temperature changes in the Trojan are very smooth and stable.

The frame work is heavy duty even by our standards. Thick angle iron gives the frame a strong skeleton, there is then and internal stainless mesh panel and a powder coated external panel with an air gap in between for ventilation.

Trojan Midi

Internal size 1000mm (wide) x 600mm (deep) x 360mm (High)

External Size 1450mm (wide) x 1200mm (deep) x 1850mm (High)

Weight 660kg

Power 18KW (you should check that your power supply is suitable,

and should be installed by a qualified electrician)

Amps 75.6A

Voltage 400v+N

Maximum Temperature 960c

Controller included ST535CWIFI

Trojan 1

Internal size 1300mm (wide) x 1000mm (deep) x 500mm (High)

External Size 1960mm (wide) x 1600mm (deep) x 1750mm (High)

Weight 910kg

Power 21KW (you should check that your power supply is suitable,

and should be installed by a qualified electrician)

Amps 88.2A

Voltage 400v+N

Maximum Temperature 960c

Controller included ST535CWIFI

Trojan 2

Internal size 1300mm (wide) x 700mm (deep) x 700mm (High)

External Size 1960mm (wide) x 1350mm (deep) x 1950mm (High)

Weight 940kg

Power 21KW (you should check that your power supply is suitable,

and should be installed by a qualified electrician)

Amps 88.2A

Voltage 400v+N

Maximum Temperature 960c

Controller included ST535CWIFI

The ST535CWIFI

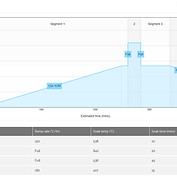

The ST535WIFI is a multi-zone controller designed for use on our larger kilns where total eveness of chamber temperature is much more difficult to maintain through simple kiln design alone. The controller monitors one section of the kiln and adjust the other sections to maintain perfect chamber uniformity with regards to temperature.

This multi-program controller is designed for glass, ceramics & pottery use. It is targeted towards glass use with 32 programs each of up to 32 segments. Each segment is a controlled heating/cooling ramp followed by a soak. It is supplied pre-programmed with 9 typical glass programs and 9 typical ceramics programs (which can be over-written).

The slow rate capability of the ST535WIFI, down to 0,1c per hour, makes it the perfect controller for complicated glass cycles.

The ST535WIFI has the capability to be accessed and controlled remotely from your mobile device.

This is one of the most important advances in Kilncare kilns for many years.

Using Kilncares GATEWay access site you can view how your kiln is running in real time. Stop the firing or adjust programs all without even being in the same country let alone the same room.

The ST535WIFI is also fitted with a USB port that allows programs to be entered that way direct from PC if required and also allows us to apply updates and run diagnostics without travelling to your kiln.

ST535CWIFI Controller features

-

Multi-zone control.

-

32 programs - each with up to 32 segments.

-

Each segment is a controlled heating/cooling ramp soak.

-

Suitable for glass or ceramics use.

-

Soak times up to nearly 100 hours.

-

Ramp rates from 1 to 999°C/hour full.

-

Program Pause & Segment Advance facilities.

-

Keypad lockable.

-

Delayed start - up to 4 days.

-

WIFI mobile access capability.

-

USB facility for fault logging and program loading.

-

Power failure recovery.

-

Energy used display.

-

Event / Damper / Fan relay output.

-

Alarm relay with alarm buzzer.

-

Mains power switch.

-

Built in the United Kingdom.

Internet access to view real time status and access data

The ST535CWIFI allows the user to access the kiln in real time from anywhere with internet access via the Kilncare GATEway on our website. The benefits of this are obvious as there is no longer the need to travel to the studio or work place to see how the firing is proceeding or if indeed the firing is going as planned.

Also in the GATEway, which is unique to each user via password access, there is a firings library where past firings can be stored and named, a notes section and a log amongst other features.

GATEway app and Wi-Fi capability

The KCR32Z WIFI allows the user to access the kiln in real time from anywhere through the GATEway mobile device app for Android or Apple, or anywhere with internet access via the Kilncare GATEway on our website. The benefits of this are obvious as there is no longer the need to travel to the studio or work place to see how the firing is proceeding or if indeed the firing is going as planned.

Also in the GATEway, which is unique to each user via password access, there is a firings library where past firings can be stored and named, a notes section and a log amongst other features.

Multi zone temperature control

The ST535WIFI is a multi-zone controller designed for use on our larger kilns where total evenness of chamber temperature is much more difficult to maintain through simple kiln design alone. The controller monitors one section of the kiln and adjusts the other sections to maintain perfect chamber uniformity with regards to temperature.

Automatic roof vents

This allows the roof vents to be opened and closed multiple times throughout the duration of the firing at the temperatures required.

The opening and closing cycle is programmed into the controller, enabling the user to start the kiln then not have to return to it for any action other than monitoring until the cycle is finished. Extremely useful on larger models where firings can last for many days or even weeks.

Even heat throughout

Heat is provided from all 4 sides and from tubed elements in the roof. This ensure that the heat from the elements is dispersed as evenly as possible throughout the kiln chamber. This is also supported by extra thick wall insulation to ensure smooth and even temperature changes.

Quartz element roof heating system

The heating system in the roof utilises the latest technology "infra-red" quartz tube heating elements. This method is extremely hard wearing and strong, yet in the event of an element failure the tubes are both easy and cheap to replace.

Kanthal A1 elements

The Trojan range, along with the vast majority of Kilncare kilns, utilises Kanthal A1 elements (which are widely regarded as the best quality elements available), ensuring unbeatable reliability and durability.

Vent/peep hole

On the front of the kilns is a large vent/peep hole, allowing for a view into the kiln to check how your firing is going, as well as extra ventilation for cooling the kiln quicker once the firing has completed.

Over-fire and door switch safety

Each Trojan has a door safety cut off switch along with a dual contactor door cut off circuit, which also acts as a dual contactor over fire protection circuit, making the kiln extremely safe.

Reliable seal and robust front face

The door seal is maintained by non-ceramic fibre that is set into a channel around the front face, which ensures it stays in place, unlike other methods of "Stick on" fibre seals which often tend to fall off.

The Front Face itself is made from "Hard" insulation bricks to reduce the damage caused by knocks and bumps during loading.

All of the kiln doors in the Trojan range are made of the same high grade insulation bricks as the chamber sides.

3 Year Warranty

The Trojan range comes with a 3 year warranty that applies for all parts (inc elements)! The fact that we are able to offer such a long warranty on these kilns just goes to show how well made they are and how they are truly built to last.

Made In The UK

The Trojan range, along with all other Kilncare kilns, is made right here at Kilncare, in Stoke-on-Trent, United Kingdom.

Unrivalled aftercare

Here at Kilncare we really do pride ourselves on our customer service. We have a team of kiln experts at hand that will be there for you whenever you find yourself with any queries or worries who will do their absolute best to ensure that you can continue your glass journey as problem free as possible.

We really do go the extra mile when it comes to customer service, which you can see for yourself by taking a quick look at our online reviews.

.png)