THE LK LEHRS

Kilncare Lehrs have been used in major hot shops for more than two decades and there have been gradual progressions as time has passed but 2022 saw the LK range take a major overhaul.

GX 2022 Energy efficient version option.

The LK - GX version of the standard LK Lehrs

will be available in all sizes.

The LK - GX will offer far superior insulation

properties to the standard LK and the result can be anything up

to a 40% saving on heat loss through the insulation. This can

amount to a considerable monitory saving if the lehr is to be used regular.

Instead of the standard insulation in the100mm wall of the LK, the LK - GX has an additional 25mm of insulation and makes good use of ultra-high performance Micropor insulation.

This vast reduction in heat loss means that the elements and switch gear of the Lehrs will be operating far less than in a standard LK and so also means a reduction in wear of the components.

However, there is a pay off to this. Cooling. LK - GX lehrs will not be ready to open the following morning even with the automatic roof vent option taken.

Custom Build Lehrs.

Something else that really adds to the appeal of the Lehrs is the options for custom build Lehrs.

Although the LK range is primarily a single, manual door designed range, we can provide Lehrs to suit the requirements or preference of the customer.

Lehrs can have double doors, hydraulic lift and drop doors or sideways slide doors.

Shown here are a couple of examples to show you the possibilities.

Contact us with your Lehr requirements.

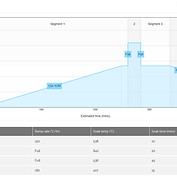

The KCR32C is multi-program controller designed for glass, ceramics & pottery use. It is targeted towards glass use with 32 programs each of up to 32 segments. Each segment is a controlled heating/cooling ramp followed by a soak. It is supplied pre-programmed with 9 typical glass programs and 9 typical ceramics programs (which can be over-written).

The slow rate capability of the KCR32C, down to 1c per hour, makes it the perfect controller for complicated glass cycles.

KCR32C Controller features:

-

32 programs - each with up to 32 segments.

-

Each segment is a controlled heating/cooling ramp soak.

-

Suitable for glass or ceramics use.

-

Soak times up to nearly 100 hours.

-

Ramp rates from 1 to 999°C/hour full.

-

Program Pause & Segment Advance facilities.

-

Can be held remotely, allowing for an easy and comfortable programming process.

-

Keyboard lockable.

-

Delayed start facility - up to 4 days.

-

Power failure recovery.

-

Energy used display.

-

Event / Damper / Fan relay output.

-

Alarm relay with alarm buzzer.

-

Mains power switch.

-

Built in the United Kingdom.

KCR32C WIFI Controller (Optional). GATEway app and internet access included.

The KCR32CWIFi is internally the same as the KCR32C but has the capability to be accessed

and controlled remotely from your mobile device via the Kilncare GATEway app or your pc/MAC.

The GATEway app for your mobile device is available for Android and Apple.

This is one of the most important advances in Kilncare kilns for many years.

Using GATEway you can view how your kiln is running in real time. Stop the

firing or adjust programs all without even being in the same country let alone the same room.

The KCR32WIFI is also fitted with a USB port that allows programs to be entered that way direct from PC if required and also allows us to apply updates and run diagnostics without travelling to your kiln.

The ST535WIFI (optional for multi-zone use)

The ST535WIFI is a multi-zone controller designed for use on our larger kilns where total evenness of chamber temperature is much more difficult to maintain through simple kiln design alone. The controller monitors one section of the kiln and adjust the other sections to maintain perfect chamber uniformity with regards to temperature.

The rest of the ST535WIFI is as the KCR32CWIFI.

ST535CWIFI Controller features:

-

Multi-zone control.

-

32 programs - each with up to 32 segments.

-

Each segment is a controlled heating/cooling ramp soak.

-

Suitable for glass or ceramics use.

-

Soak times up to nearly 100 hours.

-

Ramp rates from 1 to 999°C/hour full.

-

Program Pause & Segment Advance facilities.

-

Keypad lockable.

-

Delayed start - up to 4 days.

-

WIFI mobile access capability.

-

USB facility for fault logging and program loading.

-

Power failure recovery.

-

Energy used display.

-

Event / Damper / Fan relay output.

-

Alarm relay with alarm buzzer.

-

Mains power switch.

-

Built in the United Kingdom.

App and internet access to view real time status and access data

The optional KCR32C WIFI allows the user to access the kiln in real time from the Kilncare GATEway app or via pc from anywhere with internet access via the Kilncare GATEway on our website. The benefits of this are obvious as there is no longer the need to travel to the studio or work place to see how the firing is proceeding or if indeed the firing is going as planned.

Also in the GATEway, which is unique to each user via password access, there is a firings library where past firings can be stored and named, a notes section and a log amongst other features.

GATEway app and Wi-Fi capability

The KCR32C WIFI allows the user to access the kiln in real time from anywhere through the GATEway mobile device app for Android or Apple, or anywhere with internet access via the Kilncare GATEway on our website. The benefits of this are obvious as there is no longer the need to travel to the studio or work place to see how the firing is proceeding or if indeed the firing is going as planned.

Also in the GATEway, which is unique to each user via password access, there is a firings library where past firings can be stored and named, a notes section and a log amongst other features.

Internal rack

The internal rack and shelves are supplied with the Lehr, but the number of shelves and shelf positions depend on the size of the Lehr.

These shelves can be full, 1 shelf per layer or half shelves and so 2 shelves per layer.

The strong, flat mesh on the shelf top is held to allow expansion but prevent warping.

When not in use, the shelves can be stored under the Lehr on the shelf runners fitted as standards to all LK Lehrs.

Mineral Insulated elements.

Mineral Insulated elements provide heat into the kiln, these are very robust and also do not require a door switch.

Single throw opening system

In order to make the operation as user friendly as possible the twin door catches are now linked together and are opened and closed in one operation from a single, central handle.

The full length door handle is now off set so that it is easily accessible for both opening and closing.

When the angled handle and the twin catch mechanism are combined it allows the user to open the door catches and open the door with a single forearm of elbow to make for swift opening whilst maintaining a steady grip on the work being loaded.

Stainless steel opening frame

The LK Lehrs have a heavy duty stainless steel chamber opening frame, which keeps the kiln highly resilient against the heat that it is being exposed to.

Reliable seal and robust front face

The door seal is maintained by non-ceramic fibre that is set into a channel around the front face, which ensures it stays in place, unlike other methods of "Stick on" fibre seals which often tend to fall off.

The Front Face itself is made from "Hard" insulation bricks to reduce the damage caused by knocks and bumps during loading.

All of the Lehr kiln doors are made of the same high grade insulation bricks as the chamber sides.

Standard Manual Floor Vent

All LK Lehrs now have a manual floor vent that is used to more than double the effectiveness of the roof vent/s and so considerably increase the low end cooling time.

Standard Manual Roof Vent

All LK Lehrs now have a manual roof vent that can be opened to help ease that slow, last couple of hundred degrees which can help shave hours from the opening time when used in conjunction with the manual floor vent.

Optional automatic roof vents

This allows the roof vents to opened and closed multiple times throughout the duration of the firing at the temperatures required.

The opening and closing cycle is programmed into the controller so enabling the user to start the kiln then not have to return to it for any action other than monitoring until the cycle is finished.

Optional GX 2022 Energy efficient version

The LK - GX version of the standard LK Lehrs will be available in all sizes.

The LK - GX will offer far superior insulation properties to the standard LK and the result can be anything up to a 40% saving on heat loss through the insulation.

Custom Build Lehrs.

Something else that really adds to the appeal of the Lehrs is the options for custom build Lehrs.

Although the LK range is primarily a single, manual door designed range, we can provide Lehrs to suit the requirements or preference of the customer.

Lehrs can have double doors, hydraulic lift and drop doors or sideways slide doors.

Shown here are a couple of examples to show you the possibilities.

Contact us with your Lehr requirements.

Optional multi zone temperature control

The ST535WIFI will be the controller provided if this option is chosen, in combination with however many extra thermocouples are required to ensure evenness of the kiln depending on the kiln's size. The ST535WIFI is a multi-zone controller designed for use on our larger kilns where total evenness of chamber temperature is much more difficult to maintain through simple kiln design alone. The controller monitors one section of the kiln and adjusts the other sections to maintain perfect chamber uniformity with regards to temperature. Not only this, due to it being Wi-Fi capable, you will be able to program it and monitor firings from the comfort of your own device, whether it be your phone, or laptop, or computer etc.

4 Year Warranty

The LK Lehrs comes with a HUGE 4 year warranty that applies for all parts (inc elements)! The fact that we are able to offer such a long warranty on these kilns just goes to show how well made they are and how they are truly built to last.

Made In The UK

The LK Lehrs, along with all other Kilncare kilns, is made right here at Kilncare, in Stoke-on-Trent, United Kingdom.

Unrivalled aftercare

Here at Kilncare we really do pride ourselves on our customer service. We have a team of kiln experts at hand that will be there for you whenever you find yourself with any queries or worries who will do their absolute best to ensure that you can continue your glass journey as problem free as possible.

We really do go the extra mile when it comes to customer service, which you can see for yourself by taking a quick look at our online reviews.

Back in early 2022, glass blowing extraordinaire, Allister Malcolm (whom you may have seen on BBC's Make It At Market) was getting on just fine in his studio's hot shop which then consisted of a pot furnace, gas reheating chamber and a gas cooling oven, running firings for ten hours per day.

However, this all changed in August of the same year when Allister was informed that huge energy cost increases were on the horizon. These cost increases were so large that it forced Allister into having serious doubts and worries about not only the future of the studio, but even his own future as a glass artist. Running the hot shop on gas was just no longer sustainable, but working with gas was all that he had ever known.

After much thought and consideration, Allister made the decision to make the leap and replace the unsustainable gas ovens with more efficient electric ovens. It was around this time that he reached out to us and enquired about a super efficient annealing oven.

Volt Vessels - the first pieces to come out of Allister's super efficient GX Lehr

This was great timing as we had just released our super efficient GX upgrade option, maximising efficiency with the ultra effective micropore insulation.

Now this is where we let the statistics do the talking. After a full day of firing (including a 7 hour soak at 510 degrees Celsius and a 12 hour steady ramp down) his new GX Lehr had only used 53kWh.

This same firing in his previous gas oven was using a WHOPPING 250kWh!

To put that kind of energy saving and sustainability into perspective, over the course of a year Allister is now saving 8.4 tonnes of CO2... enough to drive around the entire planet 1.2 times!

You can watch Allister's full video on all of this here: Allister's journey to become more sustainable begins 2023 - YouTube

.png)